Installation & Service Instructions

- Grease the pump thoroughly before operating.

- Mount the pump as near as possible to the liquid being pumped and ensure that suction pipe and fittings are air tight.

- Pumps are self priming but rely on the liquids for lubrication and should not be run dry for more than 20 seconds.

- For best results do not run the pump at a higher speed than necessary, keeping within the range of 500 to 1750 rpm.

- For increased impeller life, pressures should be kept below 0.7 bar.

- The impeller is heat resistant and designed to run between 40°F and 180°F. In conditions where freezing takes place, care must be taken to drain the pump after use by loosening the cover plate.

- Petroleum derived cleaning solvents such as naptha, kerosene, benzine etc, and carbon tetrachloride, paint and lacquer thinners cannot be pumped satisfactorily. In some cases oils can cause swelling of the impeller causing binding.

- Do not hammer pulley on to the shaft as this will damage the pump internally. Do not run pump dry for prolonged periods. Do not install pump with over tight belt as this will reduce the bearing life.

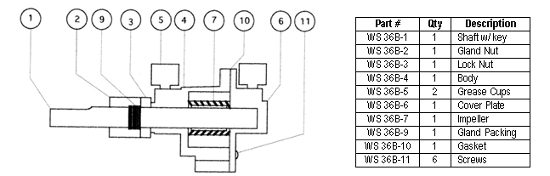

Impeller Replacement

- Undo impeller screws, remove cover plate and undo gland nut.

- Remove whole shaft with impeller, from the body.

- Remove impeller by sliding up long part of the shaft.

- Reassemble new impeller with open slot facing you and slide onto length of shaft to engage into key slot.